- Chemical protective clothing and protective clothing LIVMOA

- for Cleanrooms

LIVMOA™ Hazmat suit for Cleanrooms | Sterile Type |

Reduced dust emission, low condensation, and easy to put on and take off. Single-use cleanwear made using Toray's cutting-edge materials.

"Coveralls are too bulky..."

"Heat and moisture really bother me while working..."

Are you resigned to the fact that

working in a cleanroom has to be uncomfortable?

LIVMOA™, which is the culmination of Toray's cutting-edge materials

technical finesse, markedly improves the comfort

of the protective clothing, making the workplace more comfortable.

Breathability combined with low dust emission makes for comfort and cleanliness

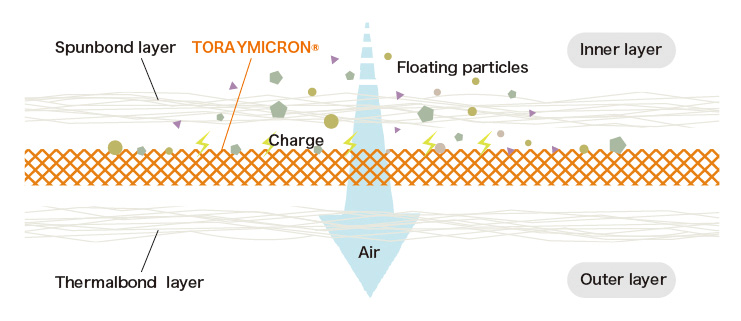

Multi-layered structured material that uses TORAYMICRON™ provides excellent breathability

TORAYMICRON™ is an electrostatic non-woven microfiber fabric that is also used in air filters, and has excellent dust collection capacity and breathability. This product reduces discomfort caused by condensation, which is an issue with conventional protective clothing. It's comfortable even in work environments where condensation occurs frequently, contributing to improved workability.

Cutting-edge materials technology resolves discomfort in the workplace

It had been taken for granted that those who need to wear protective clothing on the job would experience high humidity and a high discomfort index. Toray has achieved comfort in the workplace by fully utilizing its cutting-edge materials technology, developing a material that delivers breathability, which is necessary for wearer comfort, while reliably preventing the entry of undesirable elements such as dust and dirt. The result has been worker comfort and safety.

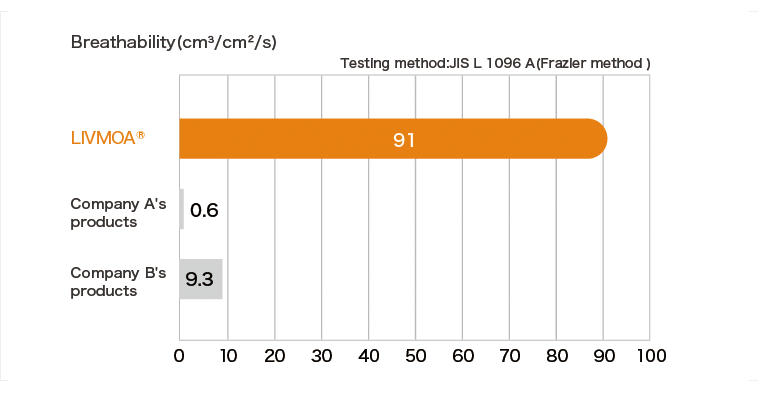

Breathability Experiment Using TORAYMICRON™

LIVMOA™ uses Toray's cutting-edge material TORAYMICRON™. This experiment compared the breathability of the materials by pasting them onto a plastic cylinder and blowing air from below.

The Styrofoam spheres in the cylinder with the LIVMOA™ barrier floated up high, indicating the superior breathability of LIVMOA™.

Experiment Comparing Material Breathability

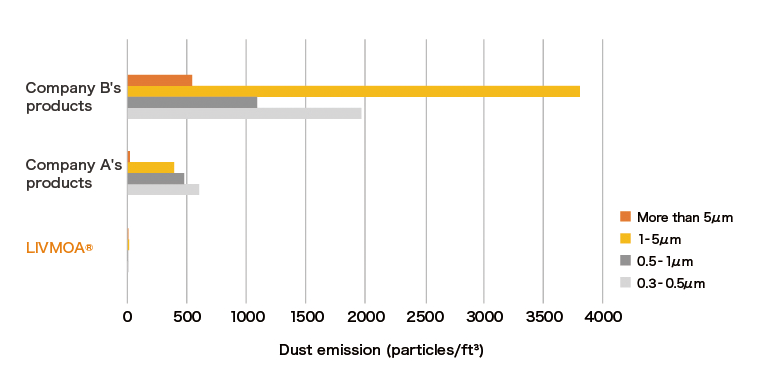

Reduces dust in sensitive cleanroom environments

Cleanliness is the number one priority in cleanrooms. It is also essential to be wary of any dust emitted from cleanroom attire. That's why we have developed this sterile clothing suitable for the regenerative medicine field, under the supervision of the Foundation for Biomedical Research and Innovation at Kobe. Not only does it provide comfort due to its high breathability, but it also minimizes the amount of dust emitted from clothing. Its separated-style design also makes it easier work while wearing, and it is even more hygienic to use.

Although it uses non-woven fabric, its dust emission has been reduced as much as to 99% compared to products from other companies (0.3 to 0.5μm compared to company B's product).

Testing procedure

• Put each sterile clothing sample into the testing machine

• 30 seconds after starting the machine, count the number of dust particles emitted

• Measure each sample 5 times in a row for one minute each. Omit the highest value and lowest value. Take the average value of the remaining measurements as the number of dust particles emitted.

Evaluation conditions (internal method)

(1) Testing method: JIS B 9923 Tumbling method

(2) Test environment: Cleanroom (Class 100)

So It's Easy to Wear

The low dust-emission properties of the material used (TORAYMICRON™) has allowed us to develop separate top and bottom parts.

To further reduce dust adhesion, the hem of the tunic and the waistband of the pants come turned up inside the packaging (patented).

So they can be hygienically put on without touching their outer sides.

Please try out a comfortable work environment in Toray's LIVMOA™